by A I M | Jan 7, 2026 | Predictive Maintenance, Ultrasound Monitoring

Ultrasound condition monitoring is a fast, practical way to “listen for trouble” in machines, utilities, and electrical gear—especially when you don’t have time, people, or shutdown windows to do everything. What is Ultrasound Monitoring? Ultrasound monitoring uses a...

by A I M | Nov 29, 2025 | Predictive Maintenance, Uncategorized

Ultrasound is one technology, but the way you collect the signal—contact vs airborne—completely changes what problems you can see and how you use the data. One Technology, Two Very Different Methods Most plant teams talk about “ultrasound” like it’s a single tool. In...

by A I M | Oct 10, 2025 | Electric Motors, Predictive Maintenance

Electrical motor analysis is how you catch motor and load problems early by looking at what the motor “looks like” electrically—without waiting for it to get loud, hot, or dead. What is Electric Motor Analysis? “Electric motor analysis” is an umbrella term. In plants...

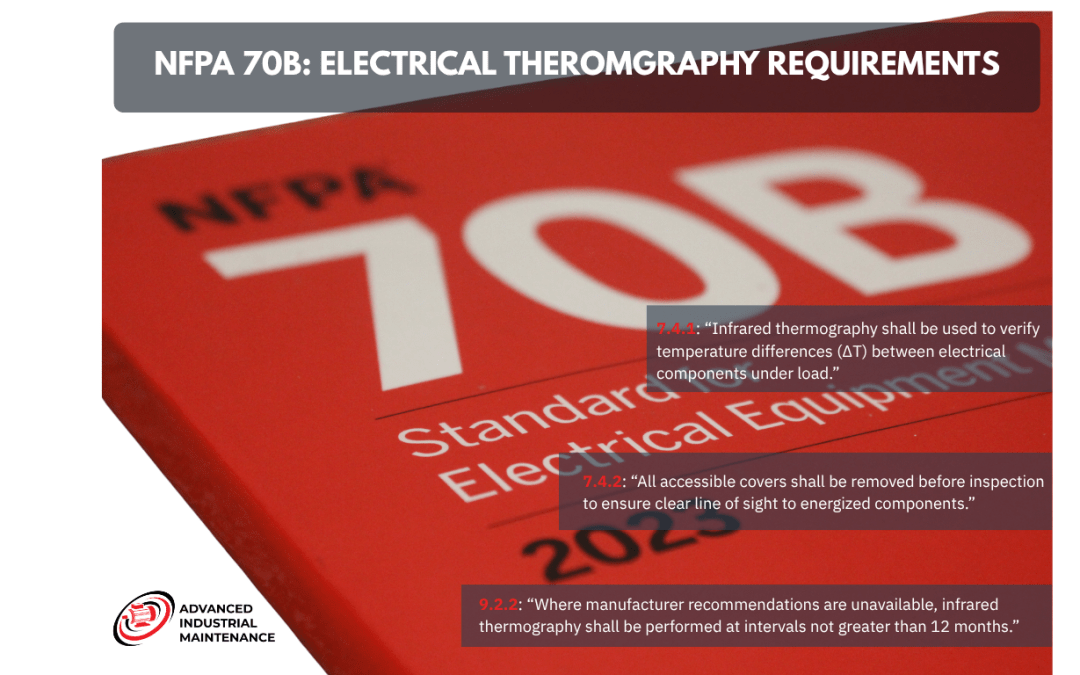

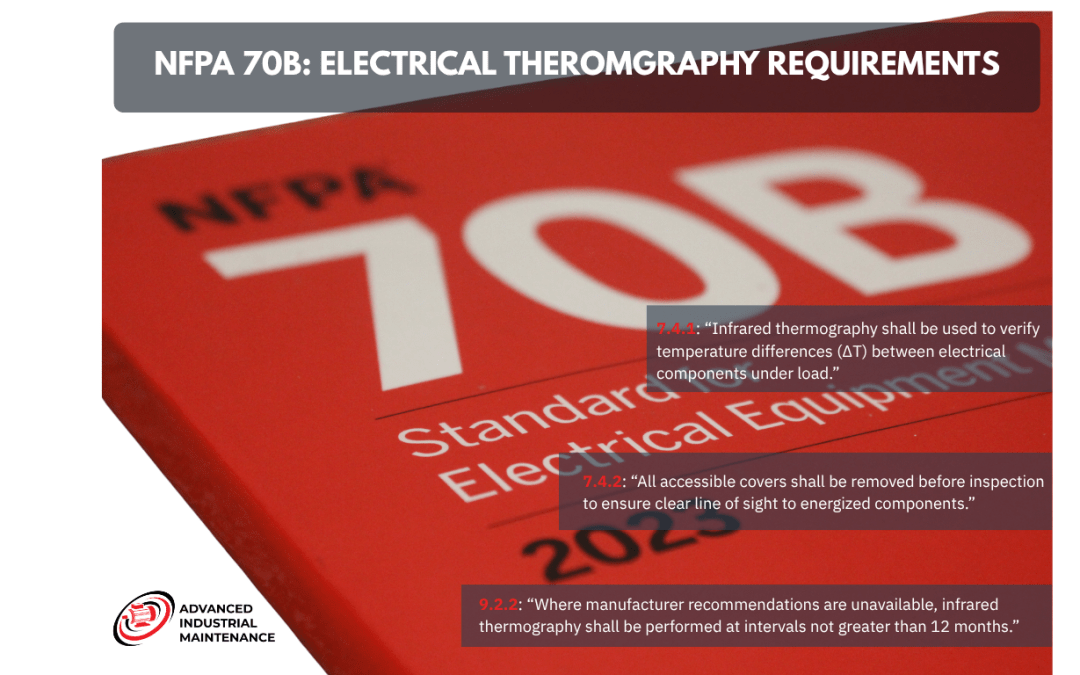

by A I M | Sep 3, 2025 | Electrical Safety, Infrared (IR) Thermography, NFPA 70B, Predictive Maintenance, Thermography, Uncategorized

Annual infrared thermography is the baseline in NFPA 70B; risk and condition decide if you scan more often. The baseline: annual scans NFPA 70B ties frequency to equipment condition. For equipment in good condition, the maintenance interval is “at least once every 12...